Fx: 86-769-8531 3421

Monica: 86-13829137016

86-13925827222monicachao@xinkeju.com

Add: Dalang Town,Dongguan City,GD.CN.

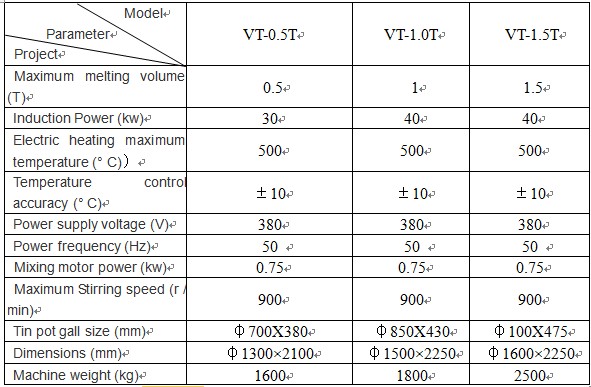

1.Technical parameters:

2.Device description:

This series belongs to high electromagnetic melting furnace melting furnace, the heating method using electromagnetic heating is specifically suited for machines with automatic casting rods supporting the use of products or directly used for casting. Mainly used for leaded and lead-free solder and tin alloy smelting. The furnace is from the melt, platforms, stirring device, exhaust system and electrical control system.

Melt the outer layer of steel plate welded structure, made of 304 stainless steel tin pot has put the tin tube leads from the bottom of the pot, put the tin tin tube is provided with a discharge valve for opening or closing the valve, tin, manual control valve by hand-pulled handle rotation tin valve, open tin after tin water valve under the action of its own weight tin pipe flow along the guide rod casting machine incubator without the use of pumping tin tin, and easy maintenance.

Platform is used to place the furnace and operating places around the platform is provided with a fence, to ensure safe operation.

Stirring means is to be tin, and the added material is completely melted, to make an additive mixed with tin, to be right. The liquid solder bath and stirred. Stirring device from the motor, and the stirring impeller axes.

With the hood stirring device can move stirrer speed to achieve frequency control, speed adjustable, can meet the technological requirements of different materials.

Exhaust means for the steel weldment movable hood is set in the furnace is provided with a holder guide pulleys mounted on the hood, the hood for the sliding cylinder, the control buttons by clicking in the furnace hoods on the body can remove the pot mouth, easy to tin-pot feeding.

Electrical control system can automatically control the temperature of each group, reaches the set temperature, the automatic warm.

This product has a furnace temperature responsive, energy saving, easy operation and practical, safe and reliable.

Smoke exhaust system must be installed according to the site produced, designed and installed by the user.

3.Features:

1. Energy efficient: cooker advantage first in its high thermal efficiency. Induction of the application of the principle is the current through the coil produces a magnetic field, the magnetic field lines within the material through the bottom of iron, iron molecules promote high-speed movement, numerous small eddy, so high thermal efficiency. In contrast, conventional heating wire heating principle is the first self-heating heating wire red-hot, then heat the air to pass through the solder pot, tin pan after heating the heat transfer to be heated tin, through multiple passes, thermal efficiency 40% -65%, and the large amount of heat energy, tin slow. The cooker is generally higher than 80% thermal efficiency, the use of heating wire heating of a ton of tin pot of water needed two hours, while the use of the cooker is only about 1 hour, saves energy and time.

2. More environmentally friendly: No combustion emissions, do not consume oxygen, no noise, no pollution.

3. Safe and reliable: no open flame burning, furnace surface itself, nor heat, induction heating only directly on the bottom of the pot, not on the surrounding produce heat, does not affect the safety of staff.

4. More precise (accurate temperature control): cooker can use requirements, flexible and accurate control of heating power and temperature of molten tin. Induction of the input power is usually 0.2KW ~ 40W between, you can choose the desired temperature, through electronically controlled, automatic tin pot is heated to reach the desired temperature, the heating appliance is immediate, fast response, temperature even more sensitive.

5 long life: the traditional heating wire will produce in the course of aging, need to be replaced in a given period, while the cooker is relatively usage time will be longer.